A good metal shop is more than a building. It’s a tool that supports your work and protects your equipment. We design and build shops that match your land and your needs. Whether you need open spans for large equipment, a combination of shop and storage, or a space with living quarters, we start with the property.

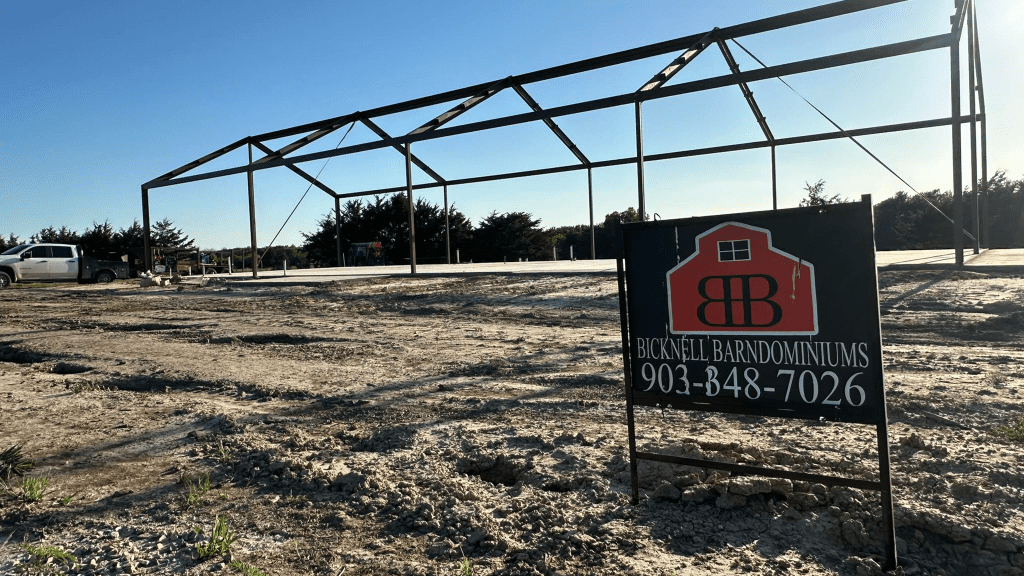

The process begins with a site walk. Slope, soil, and access all guide where the shop should sit. From there, we design around your use — tall bays for RVs, wide doors for tractors, or workrooms with climate control.

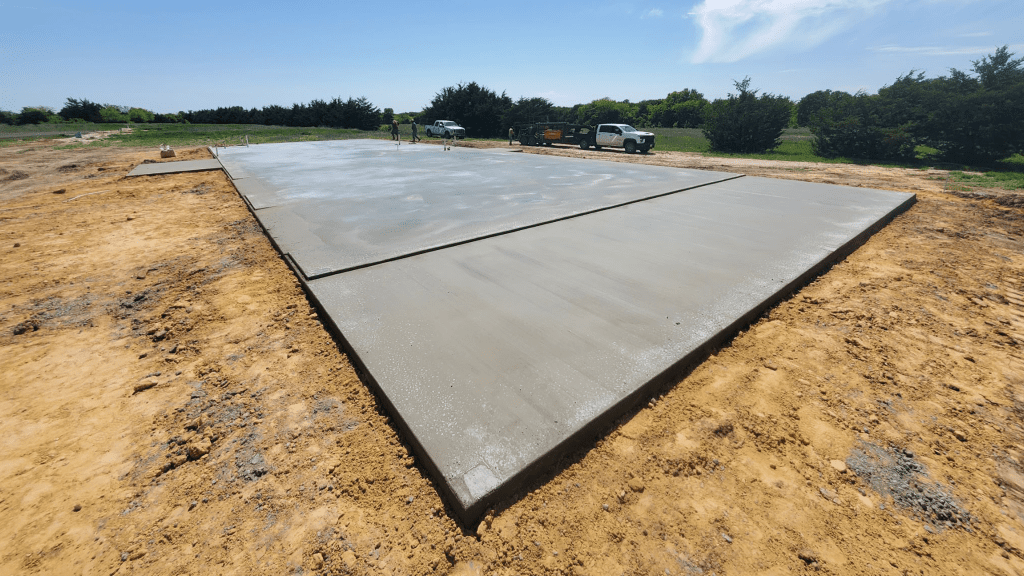

We handle excavation and pad work in house, so the foundation is solid and ready for concrete. If your acreage allows, we can cut a pond to source pad dirt and save you money. Spray foam is budgeted from day one, so your shop holds temperature and stays efficient year-round.

Our builds use red iron steel with options for bolt-up or weld-up frames. This means strength, flexibility, and the ability to expand later if your needs grow. With the same subs on every build since 2019, you get consistent quality and a tight schedule.

A shop is more than walls and a roof. It’s a place to protect your equipment, store supplies, and get work done. A metal shop stands up to weather, gives you wide open spans, and can be finished as simply or as fully as you want. Whether you need a barn-style shop, a workshop with climate control, or a mixed-use space with storage and office, we design it around your land and your purpose.

Every shop starts with a solid foundation. Our excavation is in house, handled by my husband, so you don’t wait on outside contractors. Pad work is included when we build. If your acreage allows, we can cut a pond and use that dirt for the pad. That saves money and gives you another feature on your property.

We build with red iron steel. You can choose bolt-up kits for efficiency or weld-up for maximum flexibility. Both give you the strength and durability you need. Shops can be simple storage shells or fully finished spaces with plumbing, HVAC, and insulation.

Spray foam is budgeted from day one. A typical spec is 1.5 inches of closed-cell foam on walls and roof. That keeps your shop comfortable, lowers energy costs, and adds structure. You can work in your shop year-round without fighting heat or cold.

Your land decides the layout. Open pasture may call for a wider footprint and large bay doors. A wooded site might need a tighter pad and a driveway that works with the slope. We design each shop to fit the property so it functions well and looks like it belongs.

The same subs have been with us since 2019. They know the schedule, the standards, and the pace we keep. This consistency means fewer delays and better quality on every project.

About five months with steady updates. Weather and permits can add time.

Yes. Excavation is in house. The pad is included when we build.

On acreage, a pond cut can supply pad dirt and reduce hauling.

Yes. Spray foam is budgeted from day one for a tighter, tougher shell.

Yes. We tune siding, colors, and accents to your property and style.

The same subs we have used since day one. We keep a consistent team.

Whether you want a Turn-Key Build or a Kit to start your own project, we’ll guide you every step of the way. Let’s bring your vision to life today.